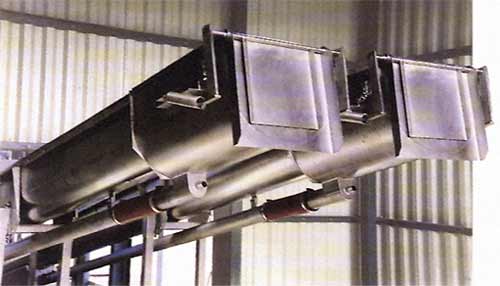

Dewatering Presses

The Dewatering Press is a extraordinary simple machine for dewatering and transportation of screen particles and wet waste. Fundamentally it is a screw carrier with at the end a press zone. The dewatering press is a trustworthy machine which can handle relatively high capacities to dewater effectively. The favourable proportions between price and perfomance make the Dewatering Press succesful worldwide in, for instance, sewage water purifications installations, paper industry, foods industry and slaughter houses.

Charactaristics

- Water will be transported through drainage

- Cleaning of the drainage section occurs through a spiral-shaped brush on the spiral

- The dewatering section is equipped with a sprinkler for automatic cleaning

- The end has a valve for adjustable back pressure

- The slot width of the press basket depends on the medium and the desired separation requirement.

Advantages

- Simple, trustworthy and affordable

- Different supply locations possible

- Takes up little space

- Arranged for the dewatering of different products.

Material

- Trough and lids: SS 316L

- Transport/press spiral: special steel or alternative Stainless Steel

- Press strainers, wedge wires: SS 316L.

Operation

The transport section of the Dewatering Press ends in a press section with a perforated hive. The spiral is hereby thus shortened that the wet medium in the press section will be compressed to a ball. At the same time the dewatering of the wet medium occurs through the pressure structure during ball formation. The back pressure is adjustable through providing the open end of the press with an ajustable valve. Transportation and particularly compression occurs by means of an extreme strong spiral. The spirals are designed especially for this purpose and can be used at lengths up until about 10 meters. The pushing drive and the open end of the installation guarantee trustworthy operation. When a Dewatering Press is provided with a logo packing system, the press will be ready for transportation, completely closed and hygienic.

| Technical specifications | ||||

|---|---|---|---|---|

| Type SA | Feed(m³/uur) | Power(kW) | Press zone length D (mm) | Friction zone length F (mm) |

| 307-U200/SP160 | 0 – 1 | 1,5 | 500 | max. 125 |

| 307-U260/SP215 | 1 – 2 | 2,2 | 600 | max. 175 |

| 307-U320/SP280 | 2 – 4 | 3,0 | 700 | max. 225 |

| 307-U420/SP365 | 4 – 7 | 4,0 | 900 | max. 300 |

| 307-U500/SP405 | 7 – 15 | 5,5 | 1000 | max. 350 |